roughing end mill depth of cut

HTC 310-4500 12 Carbide Roughing End Mill 4 Flute Fine Pitch AlTiN HTC 310-4504 12 Carbide Long Roughing End Mill 4 Flute Fine Pitch AlTiN HTC 310-4506 12 Carbide Extra Long Roughing End Mill 4 Flute Fine Pitch AlTiN HTC 830-3500 12 Carbide Roughing End Mill For AL 3 Flute Coarse Pitch Unc HTC 85228 12 Carbide Stub Roughing Mill For Al 3 Flute Fine Pitch. Heavy cuts can be achieved because our roughing end mills have a much higher effective feed per tooth than a conventional end mill.

Kor Series End Mills Dynamic Milling Vs Conventional Milling Youtube

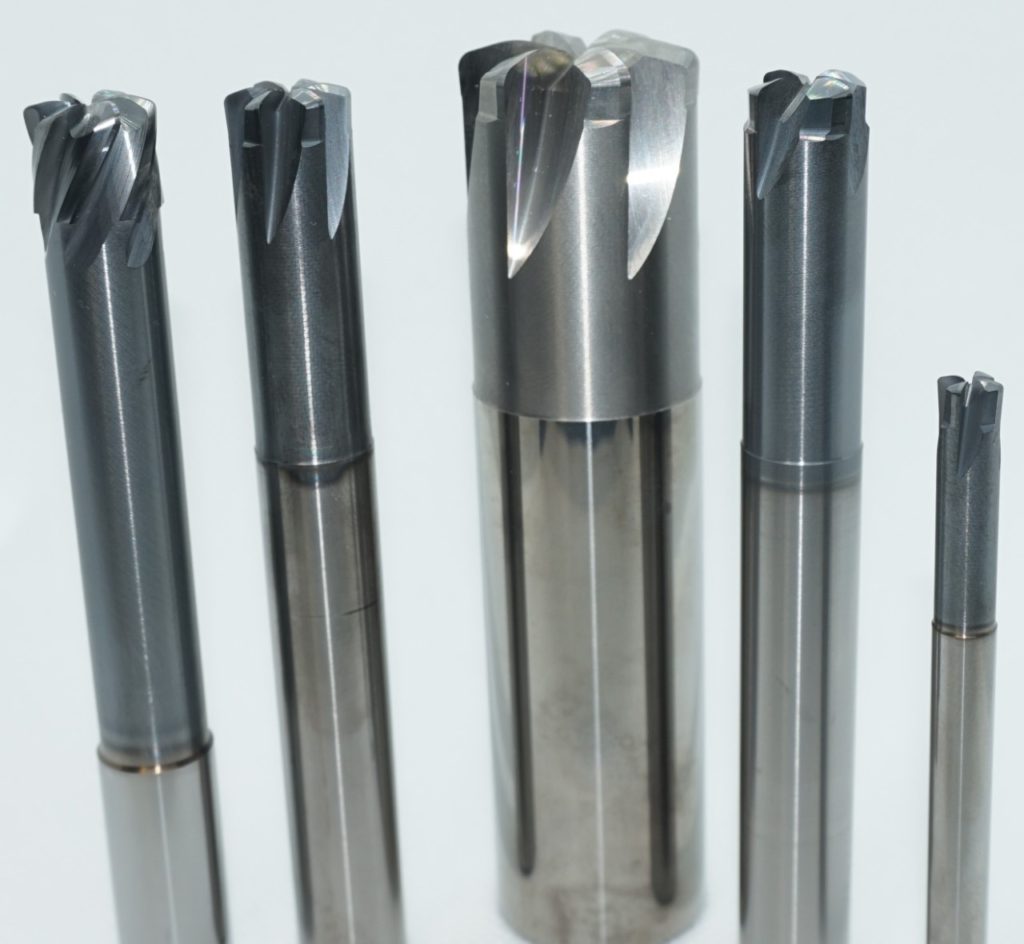

Multi-Cut end mills are specifically designed for high-performance roughing operations.

. Roughing end mill Short cut length 3 flute For aluminium alloy Corner radius roughing end mill Short cut length 3 flute For aluminium alloy. COBALT ROUGHING END MILL. This spreads wear evenly across the cutting edge dissipates heat and reduces.

Standard depths of cuts for roughing end mills can be set at a larger value than ordinary type end mills. A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. I run 600SFM 006 IPT at up to 900 depth with a 750 endmill on F22 and A105.

Side loading is dramatically reduced with lower helix angles making it easier to mill thin walls. Flute Count NOF 6. Roughing end mills also known as hog mills are used to quickly remove large amounts of material during heavier operations.

HARVI I Solid Carbide End Mill for Roughing and Finishing of Multiple Materials. During the machining process this results in chips with a finer grain and decreases vibration. Then let it haul ass.

End Mills cut rotationally in a horizontal or lateral side to side direction whereas a drill bit only cuts straight down vertically into the material. Please fill out the form below with feeds and speeds that work for you and I will place them into a new database for all to use. This means a 050-inch end mill will be engaged 0025 to 0050 inch.

Cutting speeds also vary with the end mill type - roughing end mills can go. The depth of cut for 12 inch endmill in carbide with mild steal is the dia of the tool. Overall Length OAL 6-12 Flute Type Coarse.

Choose a length that is just long enough. The image is showing. The depth of cut required for your roughing and finishing end mills is determined by the longest contact length necessary.

Multi-flute end mills create better surface finishes due to a lighter chipload - per flute. Also for the same reason the depth of cut for semi-finishing end mills can be increased. I am creating a new calculator based on your feedback.

Roughers have chip-breaker cutting edges the peaks. Roughing End Mills have scallops on the cutting edges which cause the chips to break into smaller segments. Regal Cutting Tools manufactures a variety of roughers for a wide range of materials and conditions.

Features and benefits Versatile solid carbide end mill for steels stainless steel cast iron and high temperature alloys. ROUGHING END MILLS Roughing cuts are generally for preparing the surface. Cutting tool utilization and metal removal can be maximized by fully engaging the solid carbide end mill.

End Mill Speed Feed Calculator. Vibration dampening variable flute spacing. For Taps Dies Cutting and Measuring Tools.

Normally a 20 reduction in effective horsepower is used. 45 high helix flute design. Due to variable spacing of flutes combined with the NR roughing profile vibrations cutting forces are minimized and metal removal rates are maximized.

Max depth of cut slotting with roughing end mills. Running program the other day and i notice broken 58 dia roughing HSS end mill. Depth of cut Revolution min-1 Feed rate mmmin Revolution min-1 Feed rate mmmin Dia.

Mm Aluminum alloy A7075 Cast aluminium AC4B. Cut Depth 05mm Pf04mm. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

Climb cut is recommended for side milling. Depth of Cut Maximum APMX 4 Length Group Long. Multifunctional End Mill for High Speed Roughing and Precise Side Milling Work Materials.

I replaced end mill and rerun and see end mill goes in a drilled hole 125 deep and feeds to 2nd hole a inch away at 20 ipm feed which i slow to 15 ipm feed so end mill does not break again. SFM divided by dia multi by 382 multi by IPR. The cutting speed varies with the amount of radial depth of cut when profiling and axial depth of cut when slotting.

Endmills are available in a wide variety of lengths diameters flutes and types and are chosen according to the material they are cutting and the surface finish required for the project. End Mill Terms A - Mill Size or Cutting Diameter B - Shank Diameter C - Length of Cut or Flute Length. I use the Dominator endmills by IMCO.

This is because the cutting resistance is reduced because the chips are broken into short lengths by the wavy cutting edges. Roughing end mills have cutting edges that are serrated for improved performance. AP1MAX 1st Maximum Cutting Depth AP1MAX 1st Maximum Cutting Depth L3 Usable Length L3 Usable Length.

Using Traditional Roughing. While traditional roughing is occasionally necessary or optimal it is generally inferior to High Efficiency Milling HEM. Its typical for depth of cut to be set at 2.

They are designed to remove large amounts of material quickly and more efficiently than standard end mills. Stabilizing cutting edge geometry. HEM is a roughing technique that uses a lower Radial Depth of Cut RDOC and a higher Axial Depth of Cut ADOC.

This results in lower cutting pressures at a given radial depth of cut. When I enter the cut I go 003 IPT. For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter.

The deeper you go the slower you need to go. Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Two flute end mills are center cutting where multi-flute end mills can vary.

425 Carveco Maker Sign Making For Beginners Maker Beginners Signs

Amana Tool Rc 2351 Cnc Spoilboard Insert Surfacing Rabbeting Flycutter 2 2 Flute Design 2 1 2 D X 15 32 Ch X 1 2 Shk For Thermogrip Cnc Heat Shrink Tool Hold In 2021 Router Bits Router Woodworking Woodworking

Selecting The Right Plastic Cutting End Mill In The Loupe

Milling Techniques That Make The Cut Cutting Tools Machining Technology

Pin On Rough Cut Alaskan Saw Mill Live Edge

G71 Roughing Cycle Cnc G Code Cnc Cnc Lathe Cnc Software

7 Tips For Choosing The Right End Mill For The Job M M Sales Equipment

Important Announcement Woodworking Wood Tools Diy Tools

4 6 Flute High Feed End Mills Epic Tool

More Bobcad Cam Roughing Pocketing Profiling Machining Operations

Basic End Mills Technical Information Msc Industrial Supply Co

Speed Feed Recs Melin Tool Company

Cool Jaws 5 Axis Machining Job Shop Cnc Programming

8 Ways You Re Killing Your End Mill In The Loupe

How To Make A Router Tenon Jig To Route Tenons With A Plunge Router This Is A Great Jig To Have In O Woodworking Techniques Diy Woodworking Woodworking Tools